W.W. Gay Mechanical Contractor is an NBIC and ASME certified contractor that offers excellent welding and fabrication services to industries all over Gainesville, Florida. With our Industrial ASME and NBIC Code Stamps in Gainesville, our company has the required industry experience and expertise to deliver exceptional services. Our company has a quality assurance program in place as we continue offering services of tremendous value.

We Provide of Excellent Welding Services in Gainesville

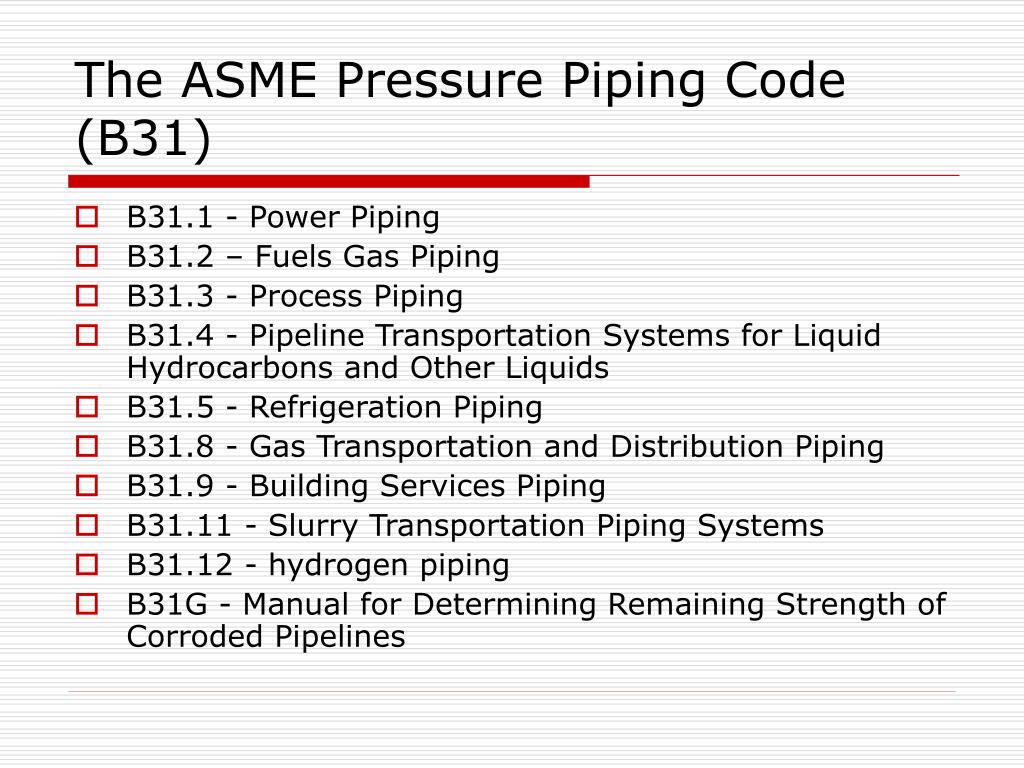

The ASME B&PV Code applies to new construction. Once the components are manufactured, or installed, or placed into service it is the NBIC that has jurisdiction with regards to in-service inspection, repair, alterations, or rerating the vessel. ASME and NBIC Code Stamps Power Boilers (over 15 psi steam, 160 psi water, and temperature exceeding 250F) shall be stamped ASME (S) and National Boiler (N.B.). The “S” stamp by virtue of its description, also covers the “PP” area or pressure piping.

At W.W. Gay Mechanical Contractor, Inc. we specialize in offering outstanding shop fabrication, welding, and field repair services. Also, we offer welding services to meet the needs of our large clientele. We work with a team of well-trained, highly experienced welding experts who possess the required knowledge and skill to design and construct pressure vessels.

What’s more, our welding experts can also help with the construction of piping systems used by industries in the nuclear power, petrochemical, aerospace, and chemical sector. We can also work on your pressure vessels and boilers. We are the right Gainesville contractor that has what it takes to handle all your welding and fabrication needs.

Superior Quality, Industry Standard Welding, and Fabrication Services

In addition to offering outstanding fabrication and welding services, our company makes certain that all our welded projects meet up with the standards and regulations of the welding industry. Our ASME certification Gainesville gives you the needed assurance that any project we handle will of a high standard.

The outcome of our projects meets up with quality assurance and certification requirements of the manufacturer. Our professional team can help with the design, manufacturing, and testing of various industrial components including Heating Boilers, Power Boilers, Nuclear Components, and Pressure Vessels. We guarantee that our pressure products will serve your industrial needs for several years to come.

Let Us Handle Your Welding and Fabrication Projects in Gainesville

Quality workmanship, prompt and excellent services, attention-to-details, outstanding customer experience, are some of the things that set us apart from other contractors that offer welding services in Gainesville. Our welding projects are of industry standard and are safe for both human and the environment.

Our ASME certification Gainesville and NBIC certification Gainesville offers the needed reassurance that our professional team has what it takes to provide excellent welding services. Above all, we offer you highly affordable services, tailored to your budget and needs.

Contact Us Today!

For more information about our welding and fabrication services or in case you will like to know more about the Industrial ASME and NBIC Code Stamps offered by our company in Gainesville, feel free to give us a call on (904)-388-2696.

Code Stamps held by W.W. Gay Mechanical Contractor, Inc.

ASME and NBIC Code Stamps Power Boilers (over 15 psi steam, 160 psi water, and temperature exceeding 250F) shall be stamped ASME (S) and National Boiler (N.B.). The “S” stamp by virtue of its description, also covers the “PP” area or pressure piping. Superheaters, economizers, and other pressure parts connected directly to the boiler without intervening valves are considered as part of this scope.

ASME-U ASME and NBIC Code StampsPressure Vessels fabrication or weld modifications of unfired pressure vessels require the ASME “U” and National Board Stamp. These rules have been formulated on the basis of design principles and construction practices applicable to vessels designed for pressures up to 3000 psi.

ASME-RRepair Certificate of Authorization and “R” stamp, from The National Board of Boiler & Pressure Vessel Inspectors, for the repair and/or alteration of boilers, pressure vessels, and other pressure-retaining items. Detailed requirements are included in the current edition of the National Board Inspection Code (NB_23).

Engineering Tips: PSV Sizing and Selection

How understanding API and ASME standards can help prevent over-sizing PSVs and their respective piping systems

NOTE: this article is written to an audience that is familiar with PSVs, PSV sizing, and API and ASME standards at a basic level. I initially wrote this article in early 2017, and due to some great input and questions made significant revisions to increase clarity in mid-2018. I hope it is helpful to you, please send me a message with any comments/questions!

The Conundrum

If you've ever sized/selected a Pressure Safety-Relief Valve (PSV) using vendor sizing programs or good-old hand calculations, you've probably run into a very strange anomaly: Why does a PSV orifice size change between American Petroleum Institute (API) and American Society of Mechanical Engineers (ASME) data sets? What is an 'effective' orifice area? How do I know which standard to use when selecting a PSV?

Usually, this issue is one of curiosity and doesn't affect the end result of what valve is chosen. Common practice is to default to API sizing equations and parameters, and only use ASME data sets for situations outside of the API letter-designations. But what if I told you that approach is likely causing you to oversize about 10% of your PSVs and their respective piping systems?

Standards referenced in this article:

- ASME Boiler & Pressure Vessel Code (BPVC), Section VIII

- API Recommended Practice (RP) 520

- API Recommended Practice (RP) 526

ASME and API : To Size or Not to Size

Most of the time simply using API data sets is fine. And I should note that this is a conservative approach, so you won’t make a mistake doing this. But did you know that PSVs are certified to ASME capacities, not API? And did you know those ASME capacities are nearly always higher than the API ones? I’m guessing you don’t, because there are very few resources available that speak to this topic. I’ve found it common for engineers to understand API 520 quite well, but have a very limited working knowledge of how the ASME BPVC comes into play.

First, let’s clarify the main roles API and ASME play on this subject, and how the standards are intended to be used:

1. API 526 provides basic design criteria for PSVs, and is aimed at manufacturers.

Asme Stamps Explained To American

2. API 520 provides detailed methods to a) determine specific required relief loads, and b) select preliminary, generic valve sizes.

3. ASME BPVC governs testing and certification of valves.

Too often, we leave that third part out of the process, and simply calculate relief loads and select valves using API techniques, without ever checking our selection against certified ASME data. Proper application of these standards is the first key point of this article:

Initial sizing and valve selection is done using API equations, and final valve selection and certification is done using ASME-certified coefficients and capacities.

When sizing a PSV, the sizing equations are always API 520. When a PSV is certified, it is always certified to ASME BPVC (whether one “selects” ASME certification or not!) It's important to remember that the ASME BPVC is the 'code', the standard to which we must design. API 520/526 are 'recommended practices' which were developed to give engineers a tool to meet the ASME requirements. Another way to look at it: ASME BPVC sets the goal, API 520/526 provide the instructions, and ASME has the final say.

ASME BPVC: What are the Rules?

The BPVC is an enormous code, and not reviewed in detail here. On the subject of PSVs, it basically says that a PSV must be capable of relieving the required load, and it must be tested in a specific manner to be certified to do so. If a valve is tested per the specific directions in the BPVC, it will be ASME certified and receive an ASME UV stamp.

NOTE: when specifying a PSV for a pressure vessel, it's important to always specify that the UV stamp is required. There are times when a non-code PSV is acceptable, but that is outside the scope of this article.

API 526: Standardized Valve Design

The first thing API does is attempt to standardize physical PSV sizes and design, and it does so in API RP 526, which is targeted at PSV manufacturers. API provides pre-defined valve sizes, with letter designations D through T (API 526). It also defines other details directed toward valve manufacturers (such as temperature ratings). All of this is intended as minimum design standards, and manufacturers are free to exceed these parameters as they wish.

API 520: PSV Sizing Equations

The second thing API does is provide standardized equations and parameters to use when trying to figure out just what size of a PSV one needs for a particular scenario. The equations account for design parameters that ASME doesn't speak to, such as specific fluid properties, backpressures, critical flow, two-phase flow, and many other aspects of fluid dynamics that will affect the ability of a particular valve to relieve a required load.

API sizing equations are by nature theoretical, standardized, and use default or 'dummy' values for several sizing parameters that may or may not reflect the actual values for any specific valve.

API RP 520 very clearly talks about this, and emphasizes that the intended use of its equations is to determine a preliminary valve size, which should be verified with actual data. API intends PSV sizing to be a two-step process, but we are often unaware of this because we (gasp) don’t read the full standard, and/or rely solely on vendor sizing software that hides the iteration from us. See API 520, part 1, section 5.2 for further explanation.

The Intersection

When valves are built, they are built to the API RP 526 standard, however, as one might imagine, when valves are actually tested and certified, the results don’t match up identically to the theoretical values that were calculated. This is where API and ASME intersect; we switch from calculations (API) which were used as a basis to design the valve, to actual empirical data (ASME) to certify the valve. When a valve manufacturer gets the UV code stamp that certifies the valve orifice size and capacity, it is based on actual test results, not API sizing standards. And ASME (which came first) does not have tiered letter designations. The typical D, E, F, etc. sizes we refer to are strictly an API tool, and ASME’s capacity certifications are completely independent of them!

An Example

Here is an example scenario where all of this comes to a confusing head:

1. ABC Valve Company builds a valve, aiming at the design specs for an API N orifice, which API says is an effective area of 4.34in2.

2. They test the final product according to ASME BPVC, and get a result that equates to an effective orifice area of 4.90in2. This is its ASME effective area.

3. A third-party Engineer (you), trying to select a PSV, runs a sizing calculation using API 520 equations on ABC Valve Company's sizing software, gets a result that requires 4.66in2 to relieve the load, and is now thoroughly confused on what size valve to select.

If one selects the API data set on the sizing software in this example, it will automatically eliminate N-orifice valves as an option, and bump the user up to a P-orifice. However, if one simply selects the ASME data set, the N-orifice valve magically reappears as an option. How can this be? Will the N-orifice work or not?

The short answer is yes, it is certified to an actual area of 4.90in2. So the “N” orifice for this specific PSV will work, and is certified to do so, in this application. Remember: use API to get you close, and ASME to confirm the final answer.

Digest that for a moment. If you’ve sized and purchased more than a dozen PSVs, chances are you have inadvertently selected a PSV a full size larger than you needed to, in a situation much like our example, simply because you chose a PSV based on its API “rating” rather than its real, certified, stamped ASME rating. If that was a small valve, impact was probably nil. But what if this happened on a valve that resulted in selecting a 8x10 PSV when you could have used a 6x8?

A More Detailed Explanation

If you’re like me, that answer isn’t very satisfying. Why on earth is this so confusing? How can you simply hit a button on the sizing program and a different size of valve is suddenly acceptable? The key lies how the main coefficient of discharge, Kd, is handled, and how capacities are determined.

There are several K values used in API calculations, all of which have generic values defined in API 520 that can be used for preliminary sizing. These are the numbers used in initial sizing calculations to get us close, then (if we do this correctly) replaced with the actual/tested/empirical/ASME values when we get a certified valve. Remember, anytime you hear “certified” or “stamped”, think ASME.

Let’s take the numbers from the example above, which came from an attempt to size a valve for liquid relief. API says to use a value of Kd=0.65 for liquid relief. If one uses the API data set on the vendor software, then the calculation stops here, and you get a required area of 4.66in2. When you select a valve, you’re comparing that to the API effective (actual) area of an N orifice, which is 4.34 in2, which is obviously too small and you’d logically step up to a P orifice. However….

Remember that the API N-orifice area is just the benchmark, a minimum requirement, and may or may not (most likely not) reflect the actual area of a real-life PSV. Once a valve is selected, all of those K values and capacities should be replaced with actual ASME-certified K values, also determined by testing, that are specific to each valve model, and the calculations performed again.

Normally, ASME-certified K-values are smaller than the API dummy values, driving up the required orifice area. So valve manufacturers have to over-design their valves to make up for it, resulting in ASME-certified areas and capacities that typically exceed the benchmark API ones. The end result of all this?

The ASME-certified capacity of any given valve will nearly always exceed its API capacity.

It (almost) all boils down to one sneaky little sentence in the ASME BPVC which mandates a 10% safety factor on the empirically-determined Kd that “de-rates” the valve (see ASME BPVC Section VIII, UG-131.e.2). This tidbit seems to be a little-known fact that is key to proper PSV sizing and selection, because as engineers we often pile safety factors upon each other and oversize our equipment. I cannot highlight this enough:

…by selecting an ASME data set at the final iteration of valve selection, you automatically include a 10% safety factor in your design!

I mentioned above that ASME K values are nearly always lower than API values, due to this 10% de-rating. The PSV in our example scenario has a determined Kd of 0.73, which is adjusted down by 10% for a final AMSE Kd of 0.66, slightly higher than the dummy API value (that just means that this particular valve proved it could do about 11% better than the minimum theoretical flow calculated by API when it was tested). So, for our valve in question, the Required ASME area is slightly less than the API area. This is atypical, but not unheard of, and again points to the importance of checking the ASME ratings of any valve you select, and comparing against the API benchmarks.

But that’s not the whole picture. For our example, the net effect of the ASME Kd is basically nothing. So how is it the ASME capacity is higher? This brings us to the last key concept:

When you choose to use the ASME data on a specific valve, it’s not just the Kd sizing factor that changes; the actual orifice area and therefore the capacity of the valve also adjusts to empirical, certified values. You can generally expect both values to increase over the API values.

Why is this? Simply that any given real-world valve is usually over-designed so that it will meet and exceed the required minimum capacity of its corresponding API size. What a simple concept, but so often overlooked by engineers!

Back to our example scenario: even though the ASME Kd, and hence required area, adjustment had a negligible effect, the actual ASME orifice area, and hence capacity, is significantly higher than the listed API area and capacity for an N-orifice. Below is a summary:

- API N Orifice: 4.340 in2

- API Calculated Required Area: 4.667 in2

- ASME Calculated Required Area: 4.624 in2

- ASME Certification for Brand X* 4N6: 4.900 in2

*Note: this is data from a real case; the specific PSV make/model is omitted. Did you catch the result? The actual, certified capacity of this valve is nearly 13% higher than the generic N-orifice valve, and that includes its 10% safety factor!

With this adjusted orifice area, we can compare to the ASME certified area (which is always going to be larger than the API area), and we have our final answer for the valve size. Often this will not result in a different choice of valve, but sometimes, as in the example case, it will allow us to use a valve with an API letter designation that did not appear large enough based on its API effective area. This can save time and money for our plants by preventing over-sizing valves, leading to smaller piping systems to support them. And remember, the ASME values are empirical and have a 10% safety factor built in, so we don’t need to worry about cutting the design too close; the conservatism is already built in to the method. We can choose the Brand X N-orifice valve and sleep well at night!

Summary

Avoid simply defaulting to the API data set for the final “rating” or data sheet when selecting a PSV. Use API sizing calculations as they are intended: for preliminary valve selection. Then switch to the ASME data set. This will often (but not always, remember, it's valve-specific) result in two differences:

Asme Code Stamps Explained

1. An actual orifice area that is greater than the standard API letter-designated orifice area. This is ok; it just means the PSV selected performs slightly better, or is slightly larger, than the minimum design conditions for its API letter designation.

2. A required orifice area that is greater than the one calculated by API. This is also ok, and is usually due to the 10% de-rating on Kd that ASME requires.

Asme S Stamp

Closing notes: PSV sizing and selection is a big topic, and this article only addresses one issue. I have chosen to omit specific code references and quotations in an attempt to make this a general guideline that is useful for most engineers, not an interpretation of the codes. Many tangent issues can spin off from this article; I will be happy to help with any questions it may generate. Please email me any comments or suggestions, I welcome all input.

Asme Stamps Explained 2020

Anytime you are selecting a PSV that is near its API capacity limits, a flag should go off in your head: remember to check the ASME capacity!